Written by Kent Penning

HVACR Instructor and President of Cold Craft, Inc.

We see a lot of very interesting but often dysfunctional heating and cooling set ups that catch our attention. We know that there are great inventions out there that are a result of people tinkering around and creating solutions, but more often than not the units that we see in place are not completing the task at hand.

Wine cellars are created to preserve wine in a cool temperature. This is one example of a hand crafted wine cellar cooling unit. Our technicians have run across several of these mystery box cooling units for wine cellars. It isn’t clear if these were made by the same person or a group and although ineffective these still remain very interesting. Initially, I didn’t really understand how this configuration worked until the technician brought in the failed components.

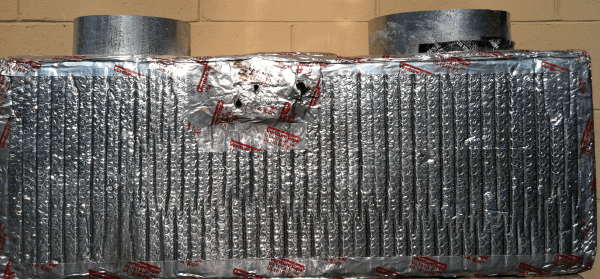

The owner of the wine cellar commented that this cooling system for this his wine cellar never worked very well, his wine was warm. The mystery box cooling unit was basically an attempt to make a ducted cooling system for a wine cellar. In that original installation someone crafted a sheet metal box that enclosed a commercial refrigeration coil that was a “wedge” shape. This was created to create an air handler to cool the wine cellar room.

This system did not work well because the propeller fan they installed to move the air, just did not have enough power to generate enough static pressure to flow the correct amount of air. If that wasn’t enough, the cooling coil was undersized and it does not have enough capacity. The lack of air flow made it ineffective. It is important to note that wine – even sealed corked wine is corrosive. The coils in these cellars need to be protected. This coil was not protected and because of the lack of air flow over the coil it took about 8 years to develop a refrigerant corrosion leak in this system. So it was ineffective as a cooling device, but the fatal blow took some time because of the weak air flow.

Cold Craft, Inc.’s solution we recommended was to replace the existing system with our custom built air handler. This air handler has a squirrel type fan instead of the propeller type to move more air and keep the wine cool. This air handler also has a stainless steel drain pan and a larger cooling coil to handle the cooling needs of this size wine cellar room. We suggest to use our specially protected cooling coil that we install in our systems to delay corrosion as long as possible.

When we completed this installation we upgraded the system with a secondary drain pan, in the unlikely event of a water leak. This was absent in the prior installation and it is a part of the current building code, thus making it a requirement. A clear “P” trap was installed so we can see on our regular maintenance appointments if any sediment is starting to accumulate in the condensate drain line – allowing us to make a correction if needed. Another way to protect the cooling coil which appeared to be missing from the original installation is to install an air filtration mechanism to keep the cooling coil clean. Although the filtration slows the air, it is needed to maintain the cooling coil and when sizing the system an allowance for the filtration needs to be included in the calculations.

The new system now has much better air circulation and more importantly maintains the desired temperature. Our customer is happier because of the more effective and efficient cooling system for his wine cellar.

If you need help with temperature, contact Cold Craft, Inc.

408.374.7292 or [email protected]

Share This Article!

Newsletter

Subscribe to our newsletter and stay updated on the latest.

Your email is safe with us, we don’t spam.